Tilt up wall construction has been around for quite some time and remains one of the most recommended construction methods for commercial buildings.

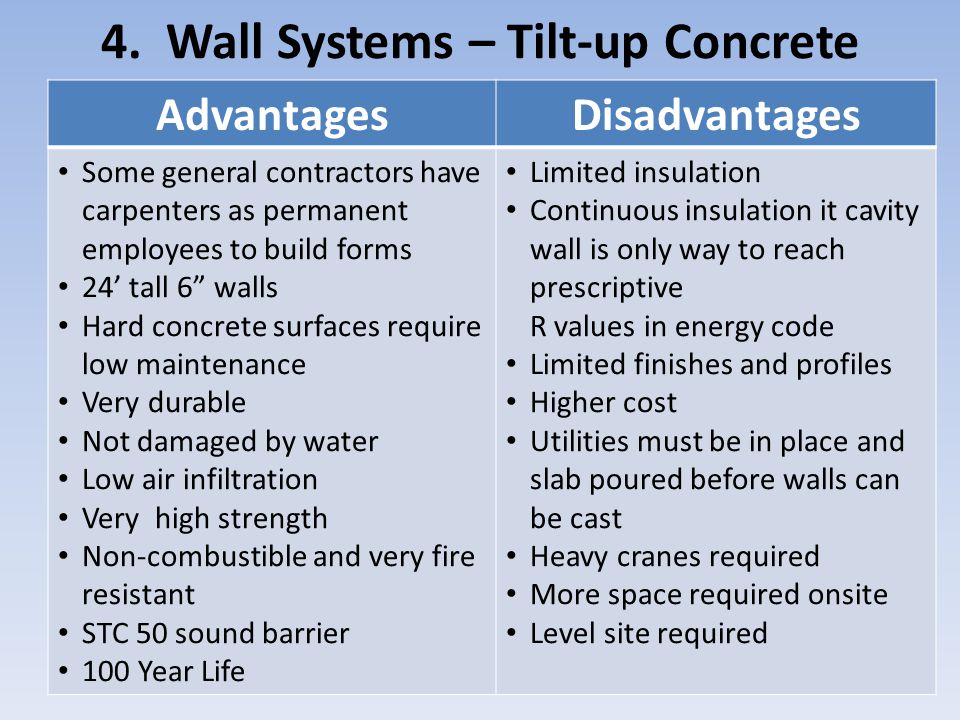

Tilt up concrete wall advantages and disadvantages.

Common production methods include tilt up poured on site and precast poured off site and transported to site.

One of the biggest advantages of tilt up construction is how cost effective it can be compared to traditional methods.

While there are several advantages to tilt up construction every type of construction method has disadvantages that must be weighed appropriately.

The major disadvantage being that there has to be adequate space for this project to happen.

Finding a knowledgeable design team.

Tilt up construction in their next project and here s why you should too.

Approximately 15 percent of all industrial buildings within the u s.

While there are tilt up building techniques that can mitigate these challenges not every site is suitable for a tilt up project.

This one two punch delivers new buildings quickly and economically which might explain why more than 650 million square feet of tilt up buildings go up every year.

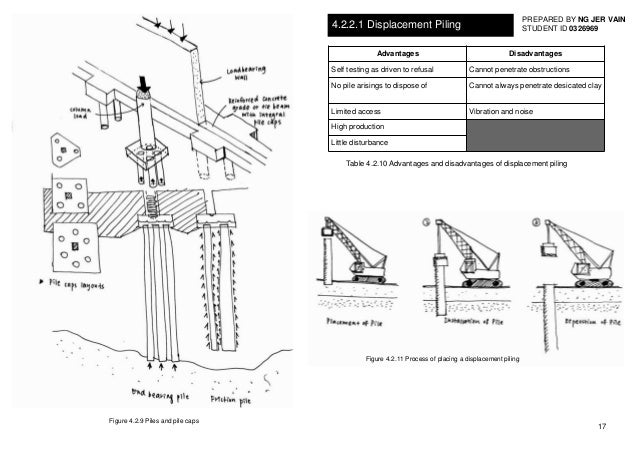

The panels are mixed either on a work platform or directly over the floor slab of the structure and are then lifted with a crane and placed over the foundation.

Tilt up construction involves site casting the concrete walls of a building on its floor slab or on a separate casting bed and then tilting and lifting them into position by crane.

Introducing the tilt up method.

The result is rapid construction arising from a well planned process more akin to a factory production line but retaining the flexibility of in situ concrete work.

Most importantly finding a design team that understands and utilizes the advantages of tilt up construction can also be challenging to the builder but the rewards are worth it.

These panels are mixed either directly over the floor slab of the structure or on a work platform and are then lifted by a crane and placed over the foundation.

It is a construction system that consists of thin on site made concrete walls which are further divided into sections that are called panels.

About the tilt up concrete association.

The tilt up method is a construction system composed of thin concrete walls made on site which are divided into sections called panels.

Tilt up construction combines the strength and durability of reinforced concrete with the precision and efficiency of the design build methodology.

There are many reasons why tilt up walls are such a.

Have been erected using tilt up walls with these buildings all being constructed for various uses and in various sizes.